PIL.

YOU´LL NEVER EVER NEED ANOTHER BELT.

This might seem like a basic product, just a normal webbing belt. But it is one of the most exciting projects we have been working on, and possibly the worlds best webbing belt.

DETAILS MATTER

RECYCLED, SOLUTION-DYED AND BLUESIGN PARTS.

This is not just any other webbing belt. It is a webbing belt where the details matter. Webbing made from 100% recycled polyester that has been solution-dyed, aluminum buckles that are Bluesigned approved and assembled and designed in a way that will make it last.

ONE SMALL PRODUCT.

ONE GIANT LEAP IN PRODUCTION.

One of the most resource consuming steps in textil production is the dyeing process. The dyeing process is basically when a textil gets its color. This process has looked very much the same for a very long time and it has one big problem; it generates a lot of waste water.

-

THE WATER - PROBLEM.

One of the biggest problem with textile production today is the coloring process.

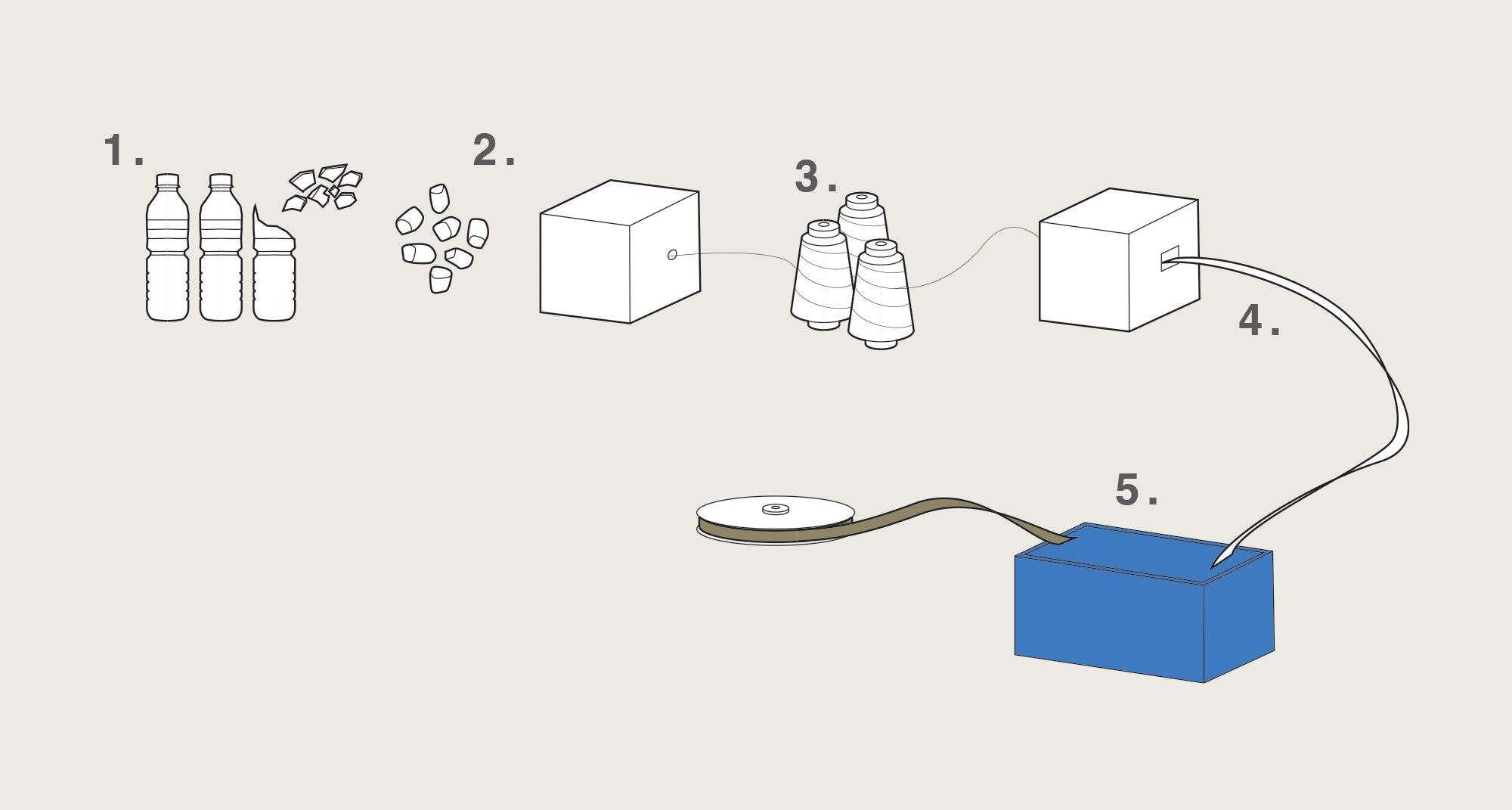

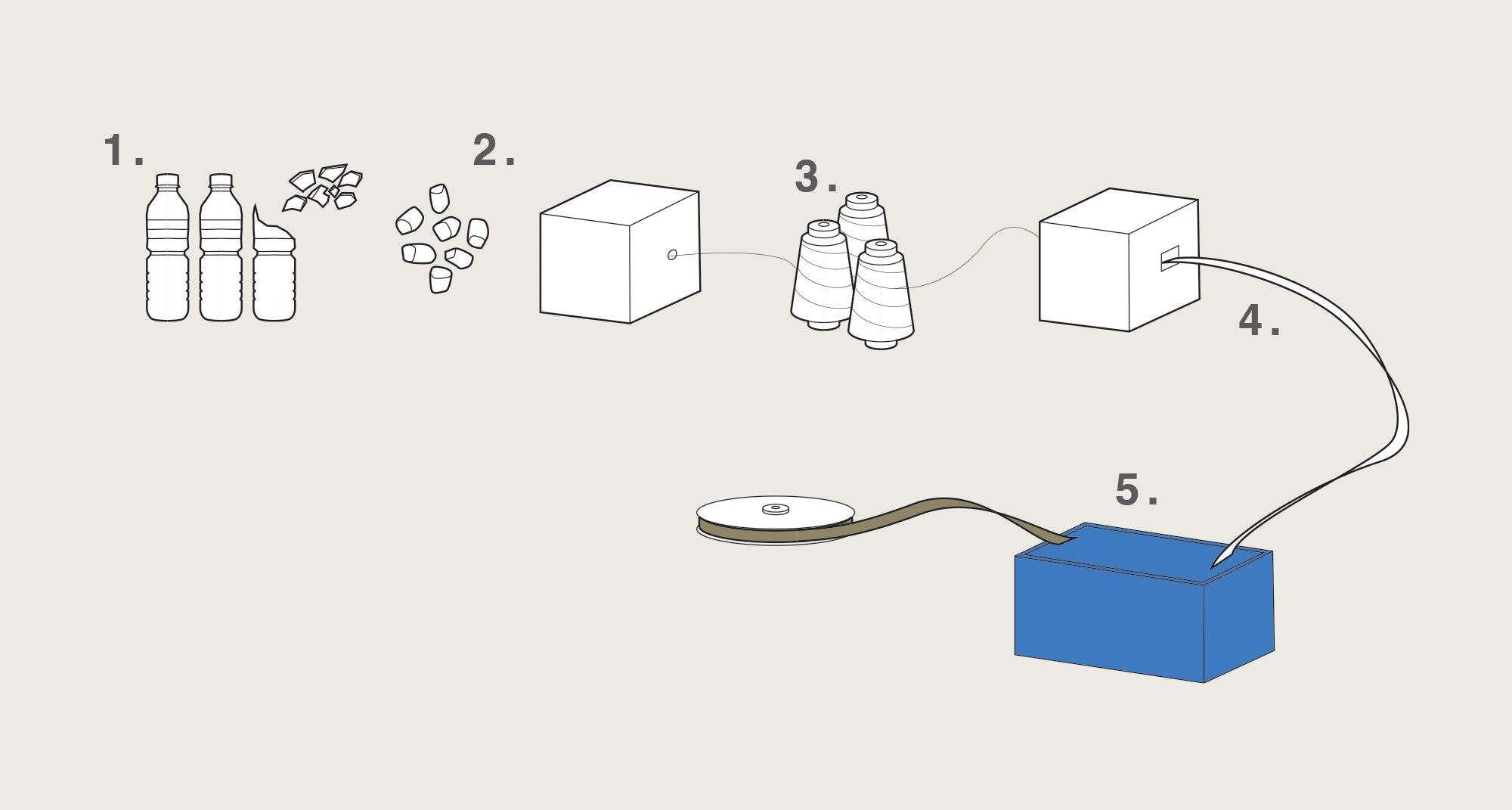

This process is a very water and chemical intense process that generates large amount of waste water.For a recycled polyester textile the traditional production process looks like this:

1. Plastic gets recycled and cut into small flakes.

2. The plastic flakes are turned into small plastic pellets.

3. The pellets are melted and extruded into a yarn.

4. The yarn is then used to weave for example a fabric.

5. The fabric then goes through a coloring process that creates up to 22 liters of waste water for every yard of fabric made. -

THE SOLUTION - DYE.

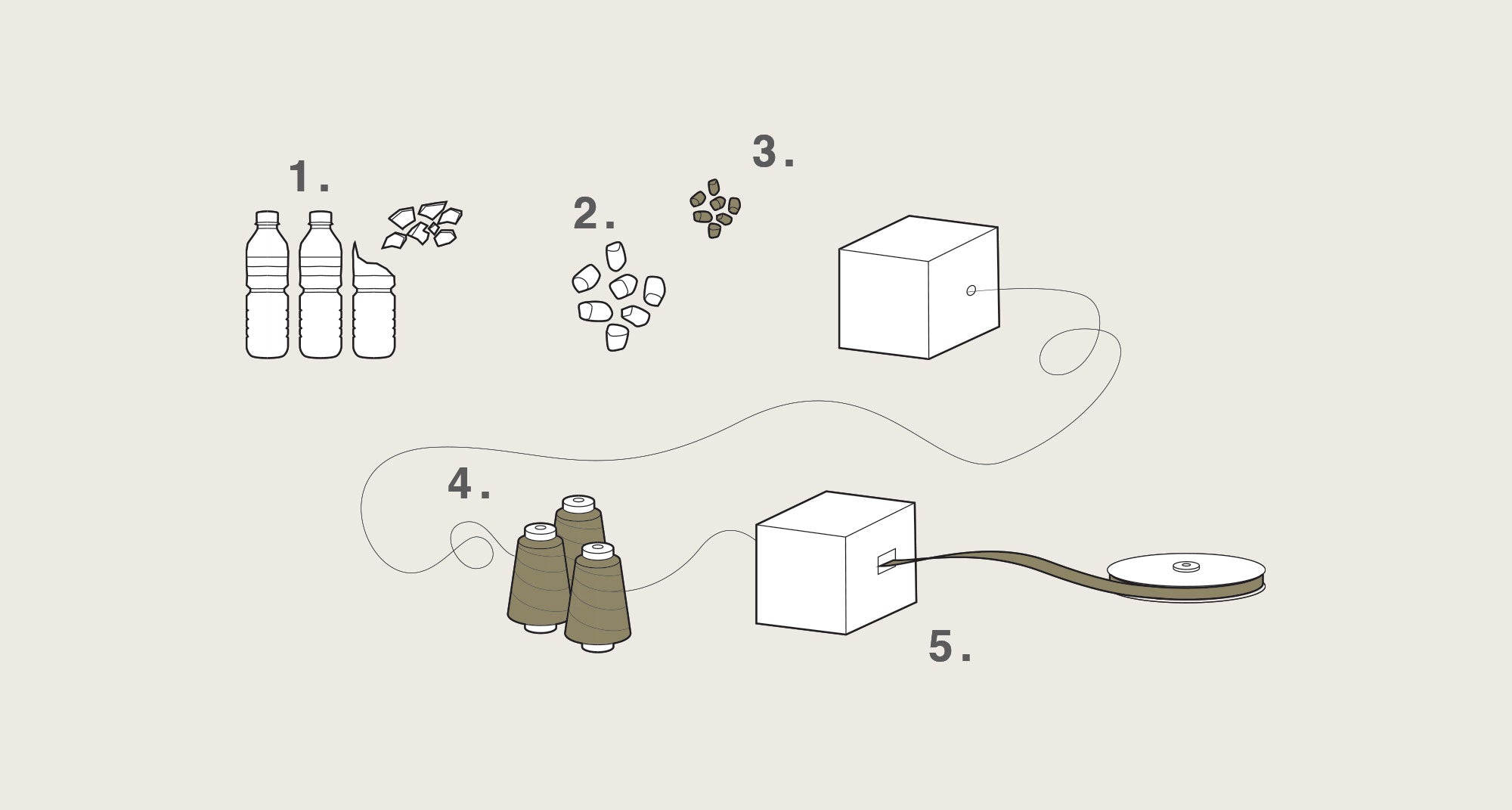

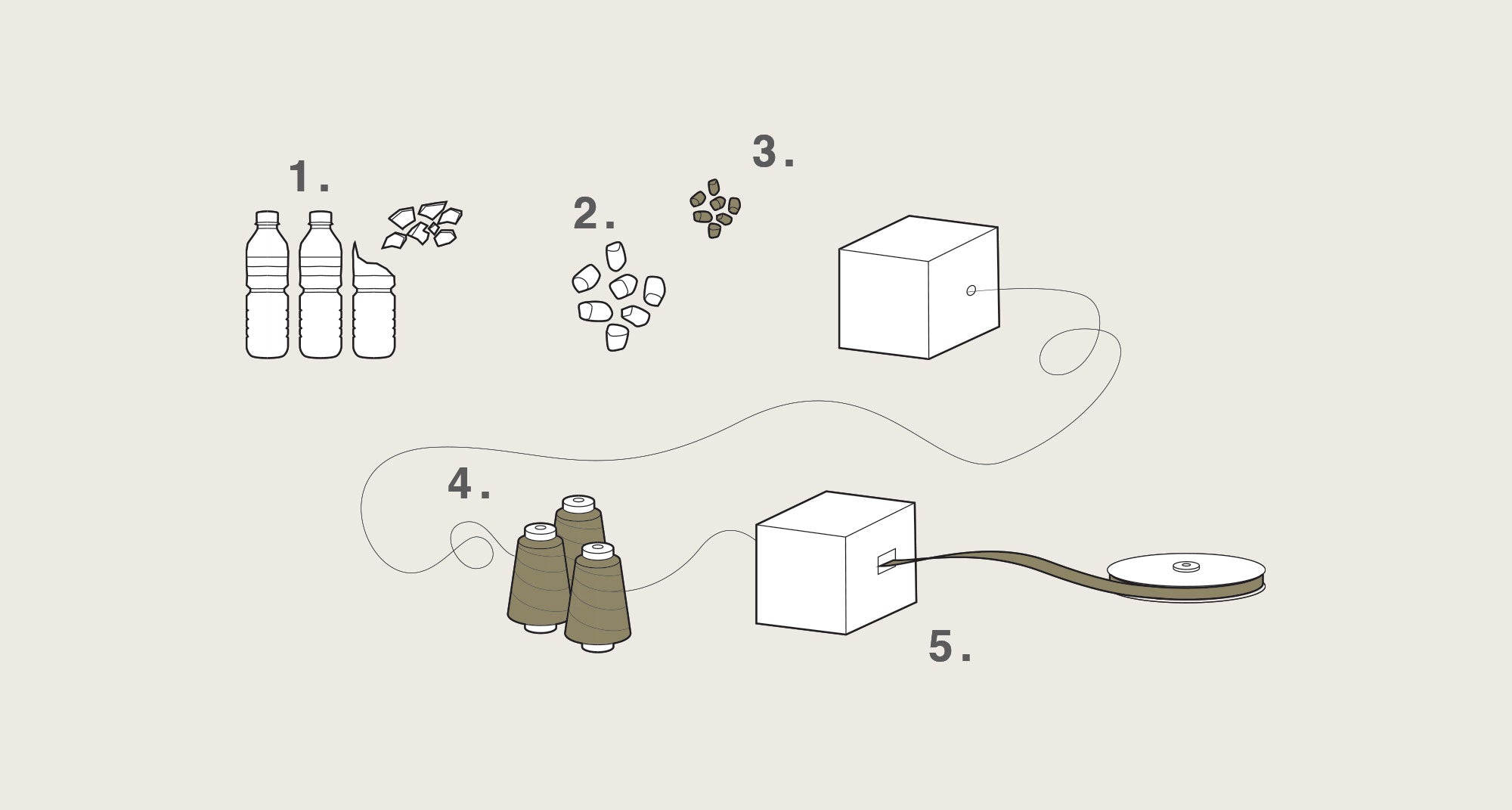

One of the most interesting solutions to this problem is called Solution Dye.

This is very much a similar process but with one big exception, the need of water is removed from the process.

Instead the colors are added already before the pellets are turned into a yarn.1. Plastic gets recycled and cut into small flakes.

2. The plastic flakes are turing into plastic pellets.

3. Pre-colored pellets are added into the mix.

4. The pellets are melted and extruded into a yarn.

5. This yarn is then used to weave a finished and colourful fabric. -

ONE SMALL PRODUCT.

You have to start somewhere and this is where our Solution Dye journey begins. We have found an opportunity to implement this technology on an extremely usable product, a belt. The use of belts has been documented back to the Bronze Age and be made from many different material and formed in many different shapes during the centuries since.

We have now set a new standard making belts. Pil is made form 100% recycled polyester with the solution-dye colouring process and as far as we know, this makes Pil, the most responsible webbing belt in the world.

WE CHOOSE TO GO TO RÄTTVIK.

BUT THERE ARE PLENTY OF PLACES IN THIS PUZZLE.

The final step in the Pil production journey takes place in Rättvik, just next to the lake Siljan in Sweden. Here you find a great sewing company called Fauna. Their sewing knowledge dates back more than 50 year. Click here to see how it looks when Pil is getting cut and sewn.

Even though a belt can seem to be a simple product, when breaking it down into all its components there are plenty of places it touches before reaching your hands. The buckles are made by UTX with its origin in China as well as the solution-dyed yarn and webbing. See the Pil specs-list at the bottom of the page for a full list of ingredients.

FUNCTIONS.

MORE THEN JUST ONE.

Keeps your pants in the right position or your gear neat and tidy.

-

Keep your gear neat and tidy.

-

Haul whatever you need to bring.

-

120cm long and 3,2cm wide.

-

Keep your pants in the right position.

PIL SPECS.

-

WEBBING.

Solution Webbing:Solution-dyed 100% recycled Polyester.Origin: Weaving and finishing in China. Yarn is Oeko-tex Standard 100.

-

TRIMS.

D-rings: Aluminum.

Origin: Aluminum from China. Finishing in China. Bluesign approved.Thread: 100% polyamide.

Origin: From Coats, Exact origin in search. Oeko-tex Standard 100.Brand label: 100% polyester.

Origin: Polyester from China. Weaving and finishing in China. Oeko-tex Standard 100.